加工技術のご紹介

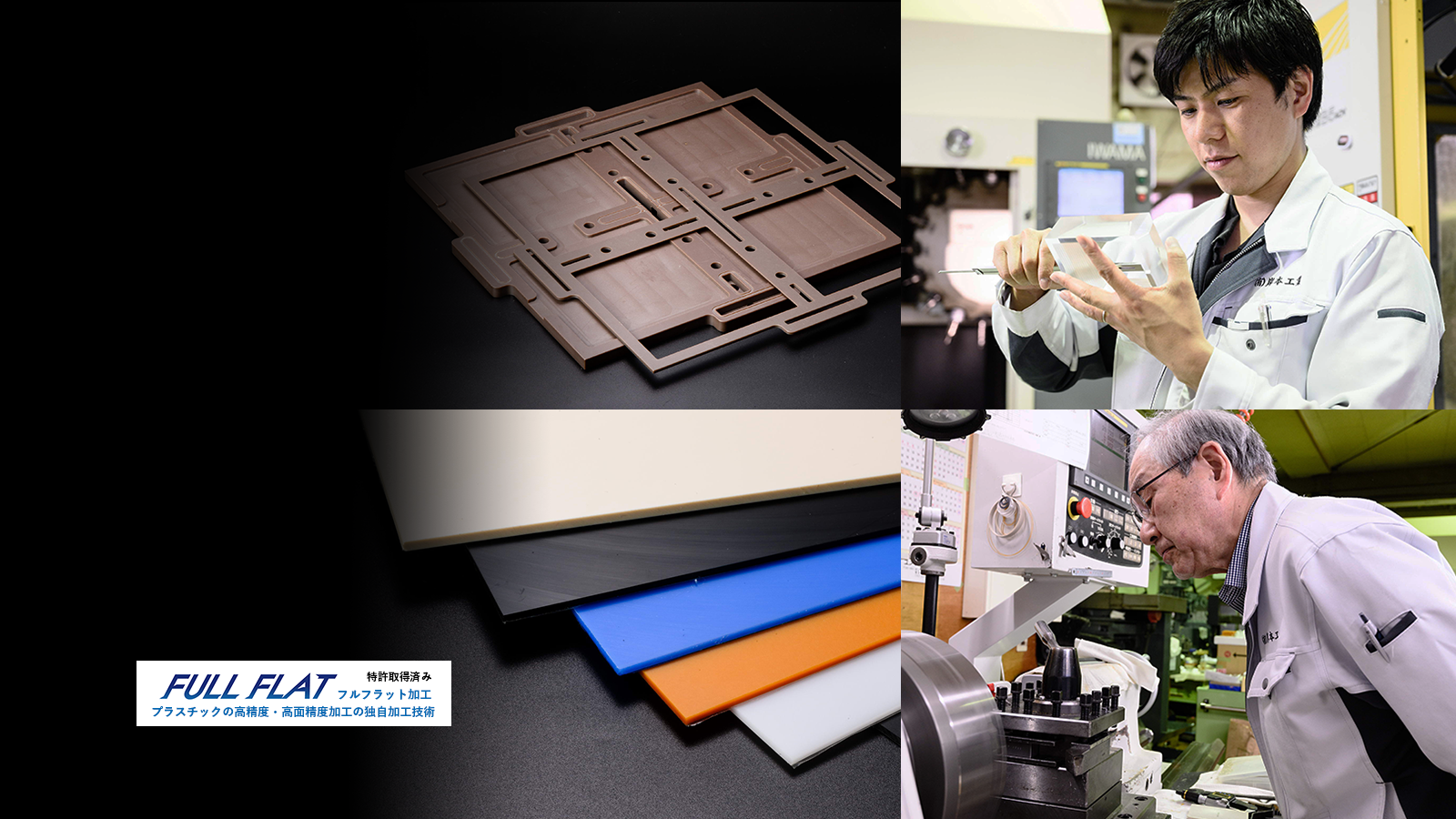

岸本工業は、プラスチックの板厚を±30ミクロン以内の寸法精度で安定的に加工する技術「フルフラット加工」を武器に、樹脂材を金属と変わらない精度での加工を実現しています。

Introduction to Machining Technology

Kishimoto Industry's Full Flat Machining technology, which allows us to stably process plastic sheet thicknesses to within ±30μ, enables us to machine plastic to the same level of dimensional accuracy as metal.

精密部品加工

精密部品加工

可視化部品加工

可視化部品加工

プラスチック

プラスチック

各種治具設計製作

各種治具設計製作

試作/研究開発支援

試作/研究開発支援

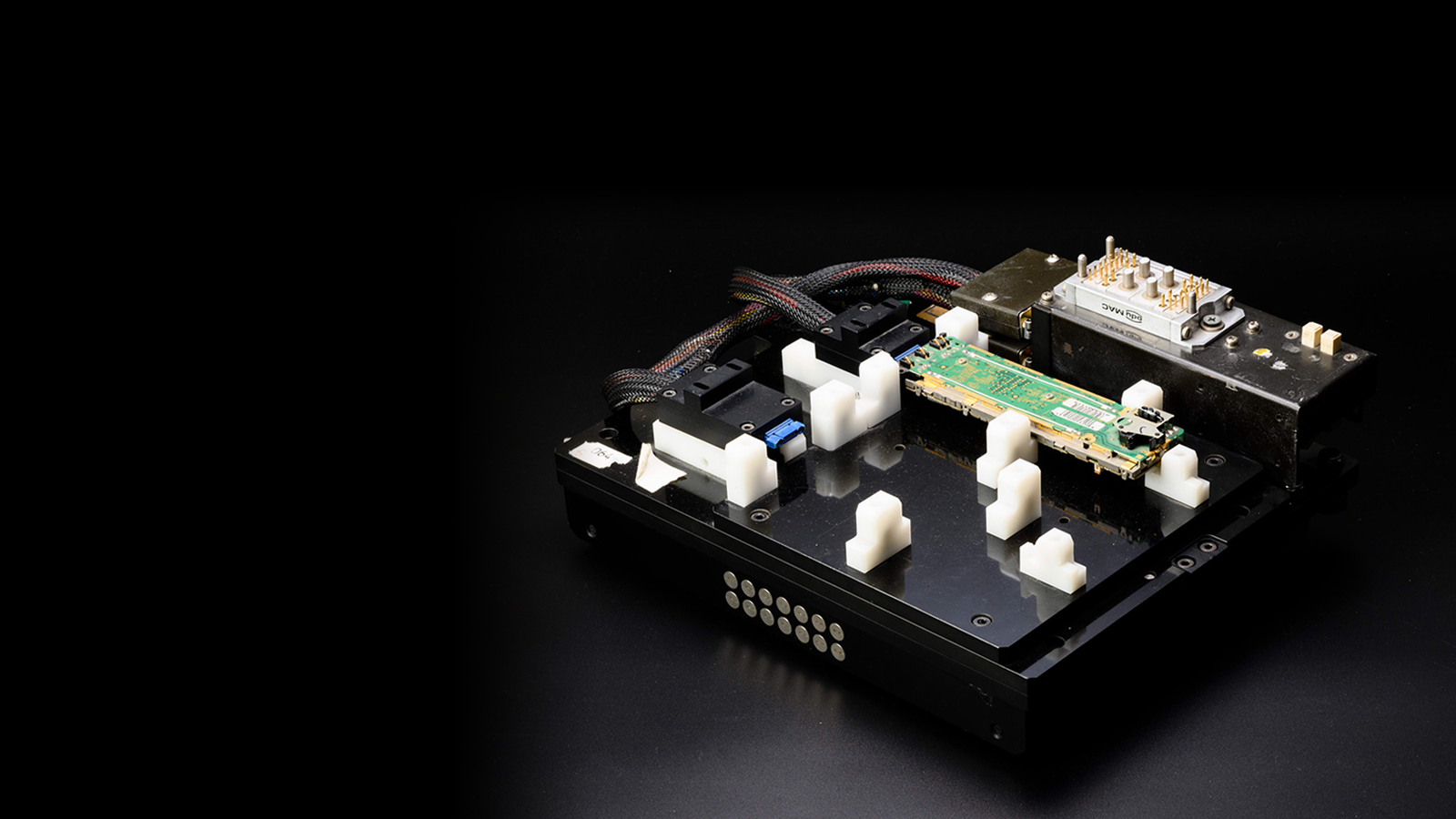

アッセンブリー

アッセンブリー