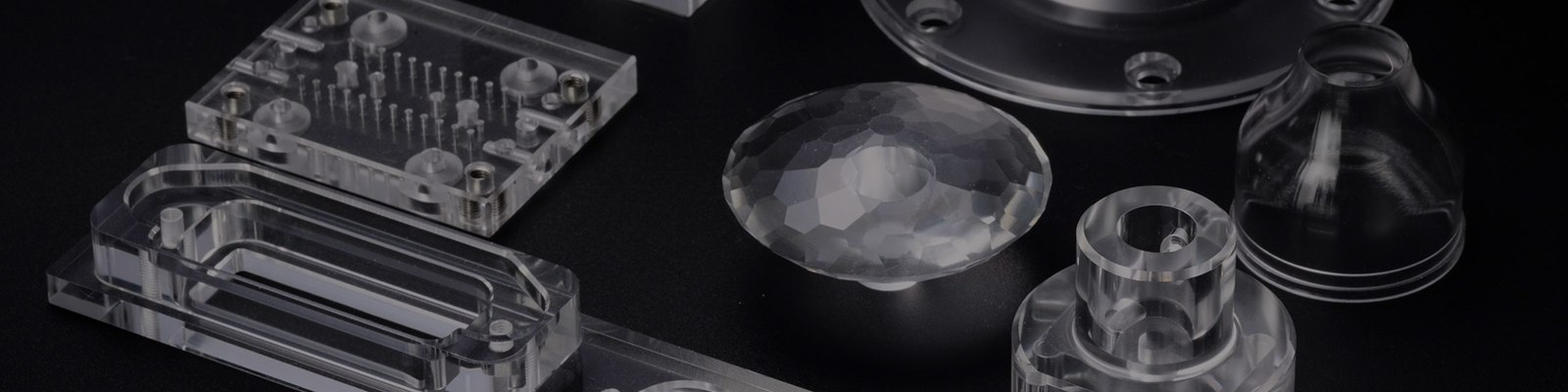

Acrylic visualization is one of our strongest technologies. Visualization machining is a technology that responds to the demands for visualization of internal flow and movement, such as fluid confirmation, and observation of the inside of machines and equipment with a camera. Kishimoto Industry has the technology to machine the inside of the hole with high transparency and to reproduce the fit with metal parts. Another important feature is that the surface is not deformed and the printing process can be applied in an accurate manner. We have a wealth of experience in fluid observation and internal visualization, especially at the request of research and development organizations and equipment manufacturers.

Why to Choose Kishimoto Industry

Acrylic is used in a wide range of applications because of its transparency, which is its greatest feature. Normally, after grinding to the desired shape, the surface can be polished to reproduce transparency, but dimensional accuracy is lost. Our visualization machining is not just about planing in a clean cut manner, but also about accurately reproducing the dimensions and being able to use it as a mechanical part. Visualization machining is one of the reasons why many designers and researchers choose us.

Confirming Transparency Level

Since transparency is highly dependent on the subjectivity of the ordering party, the level of transparency required depends on usage. We will listen to your instructions such as “We want the text inside to be visible” or “We want to film with a high-precision camera”, and in some cases, we will compare and adjust the transparency level using the sample before manufacturing it.